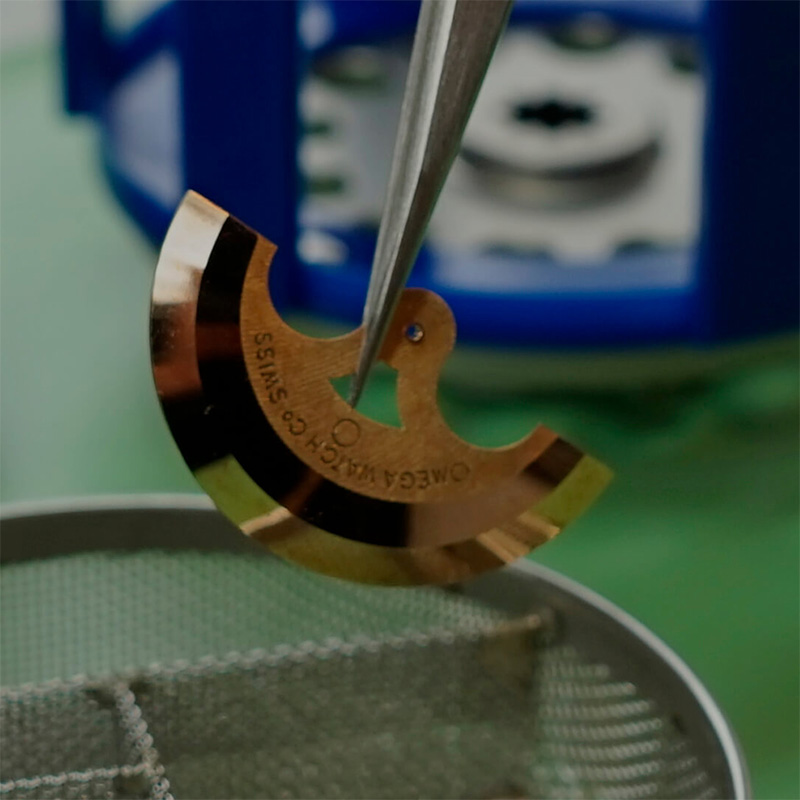

Precision Servicing & Repairs by an Accredited Watchmaker

We have designed our watch repairs and watch service procedure to ensure that every watch leaving our workshop complies with it’s original function. We are Swiss WOSTEP and BHI trained watchmakers plus we are an official Omega service centre, TAG Heuer and we are a Rolex accredited watch company.

Our comprehensive watch service procedure is one of the best in the country and this sets us apart from other independent watch repair companies.

All of our watch repairs and servicing are carried out in house at our bespoke workshop in Lymm, Cheshire. Below highlights some of the procedures your watch goes through if you choose Prestige Time Services to service your watch.

Our services & repairs process

An introduction to the meticulous 10-step procedure for servicing & repairs.

Glasses, crowns & pushers repairs & replacements

If your watch’s crown or pushers are damaged or worn, we can replace them to ensure your watch remains water-resistant. Over time, screw-down crowns can become stripped, and pushers may loosen or detach due to accidental knocks. These issues are common, and our expert watchmakers carry out such replacements regularly.

We also offer replacement services for watch glasses, whether they are plastic, mineral, or sapphire. A scratched or cracked glass can affect both the appearance and functionality of your watch, and replacing it can restore its original clarity and protection.

Using high-quality components and precision techniques, we ensure that all crown, pusher and glass replacements meet the highest standards. Whether your watch needs a minor repair or a complete overhaul, our workshop is fully equipped to handle it with care.

Bracelet & Watch Strap Repairs and Refurbishments

We specialise in repairing watch bracelets and supplying new links, clasps, buckles, and straps. Most watch bracelets can be restored, whether they have broken links or worn components. Our expert team ensures that each repair maintains the integrity and style of your timepiece.

We source spare parts from major Swiss watch brands, allowing us to provide authentic replacements for various models. If your bracelet has become loose or damaged over time, we can often restore it to its original condition with precision repairs and adjustments.

For certain models, we also offer re-riveting services to strengthen worn bracelets. A great example of this is the original TAG Heuer SEL bracelet, which we can expertly refurbish. Whatever your bracelet needs, our workshop is fully equipped to handle the repair with care and accuracy.

Why trust Prestige time services?

With over 20 years of experience, we offer accredited Swiss watch servicing, using genuine parts and advanced techniques to ensure precision, reliability, and the highest standards of craftsmanship.

20 years of experience

Over 20 years of experience in Swiss watch servicing.

manufacturer-approved

Manufacturer-approved service techniques. Rolex and TAG Heuer Accredited. Omega Service Centre

world class workshop

Advanced tools and technology for precision repairs.

postal repairs

Secure and insured postal repairs for peace of mind.

Brands we specialise in

How it works…

Request a quote

Use our handy contact form to describe your watch and what service is needed.

send your watch

Package your watch and securely send it to our workshop in Lymm, Cheshire

receive your watch

We will contact you once your watch is ready and send it back.

Ready to restore your timepiece?

Ready to restore your timepiece?

Trust our expert watchmakers for precision servicing and repairs.

Contact us today to give your watch the care it deserves.