State-of-the-Art Watch Repair Workshop

Our workshop is equipped with some of the latest tooling and equipment from Rolex, Omega, and TAG Heuer, ensuring we provide top-quality service for your watch. We also use traditional tools that are no longer manufactured, as well as the latest Swiss tools, allowing us to combine classic techniques with modern precision.

Unlike internet service agents that send watches off to third-party repair companies, we handle all servicing and repairs on-site at our fully insured (TH March) workshop in Lymm, Cheshire. This means your watch is in the hands of our skilled technicians from start to finish, ensuring the highest standards of care and craftsmanship.

Our Specialist Equipment

We are proud to showcase our equipment and workshop, which you can explore through the images and descriptions on this page and throughout our website. This commitment to quality, along with our in-house services, sets us apart from other watchmaking, servicing and repair competitors.

Ergonomic watchmaker benches

Our Swiss watchmakers benches come with ergonomic arm rests. These are situated opposite a large window for natural daylight to aid the watchmakers. The drawers are full of all the specialist watchmakers hand tools and branded Swiss movement holders. Our benches also have compressed air and vacuum lines.

Auto-winders

Auto-winders simulate the wrist and move a serviced automatic watch through different positions thus winding up the watch. When the watch is fully wound it’s then placed on a duration test before it’s ready to be returned to the customer.

water resistance testers

Our three wet and dry pressure and vacuum testers are manufactured by Sigma SA and Rolex. We have a combination of testers to simulate different conditions to test the newly fitted gaskets, crowns, case tubes and glasses after a service and a reseal. We also have a condensation warm/cold shock tester.

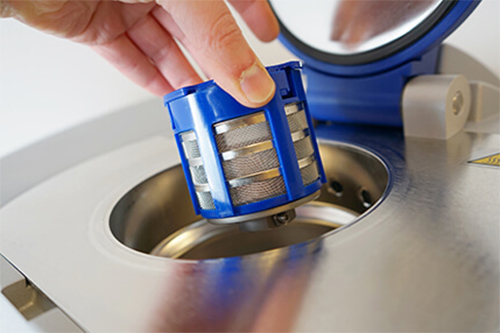

Elmasolvex VA cleaning machine

This is our latest watch movement cleaning machine. Fully stripped down mechanical and quartz movements go into special baskets to protect the minute parts and then they are placed inside to be cleaned in specialist fluids inside an ultrasonic vacuum chamber. This cleaning machine manufactured by Elma offers phenomenal deep cleaning. A link to a video on how it actually works is here.

Sigma SM-8850 pressure tester

Our dry vacuum and pressure tester by Sigma SA. This pressure tester can test up to 30 bar (300 meters) and vacuum test to -0.7 bar. We have programmed in various different test scenarios for each kind of water resistant watch.

Condensation shock tester

The machine in blue is our condensation shock tester, it’s manufactured by Rolex and features a warm plate and also a cold plate. Watch cases sit on the plates and we look for a condensation build up under the glass to see how well sealed the case is.

Rolex Fathometre WPT1 Wet tester

This is our deep wet pressure tester. Manufactured by Rolex the WPT1 can pressurise its chamber up to 120 bar (1200 meters). All our Rolex watches in for a service go in here to be tested.

Rolex 1050 wet vacuum tester

This wet vacuum tester is great for finding leaks. A watch case is submersed and then a vacuum is created. If the case leaks, a clear trail of bubbles rises to the top. It saves a lot of guessing which gasket might be failing.

Steamer & ultrasonic tanks

In one of our clean rooms we have our sinks, ultrasonic tanks and our pressurised steamer. Watch cases and bracelets are washed cleaned in the tanks then steam cleaned to remove and trapped debris. The cases and bracelets come out spotless.

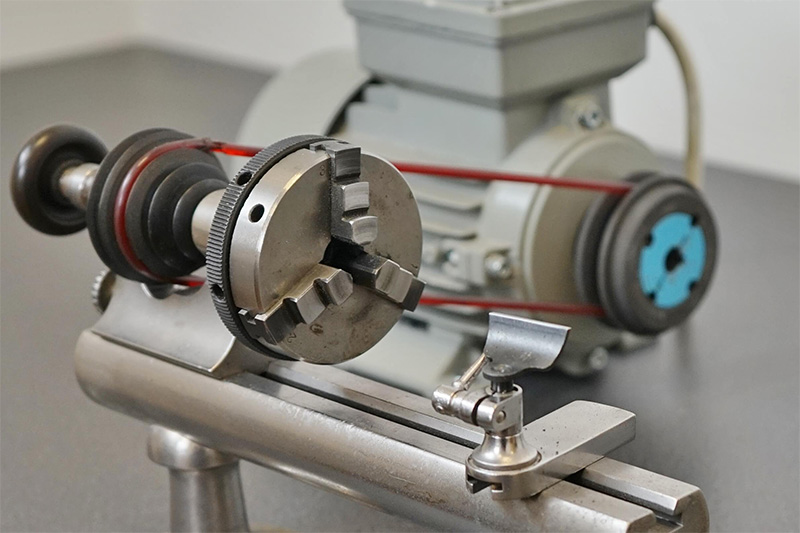

Watchmakers lathe

Our watchmakers lathe is used for making and modifying watch parts. It’s also used for refinishing watch cases including case backs and bezels. This traditional lathe has an electronic digital speed controller.

Polish machines

We have quite a few polishing machines set up with different mops for various compounds. We have Manhattan wheels as well as Arti-flex and Bufflex wheels. We can polish and re-finish any type of watch case.

Brands we specialise in

Ready to restore your timepiece?

Ready to restore your timepiece?

Trust our expert watchmakers for precision servicing and repairs.

Contact us today to give your watch the care it deserves.