Precision Restoration by an Accredited Watchmaker

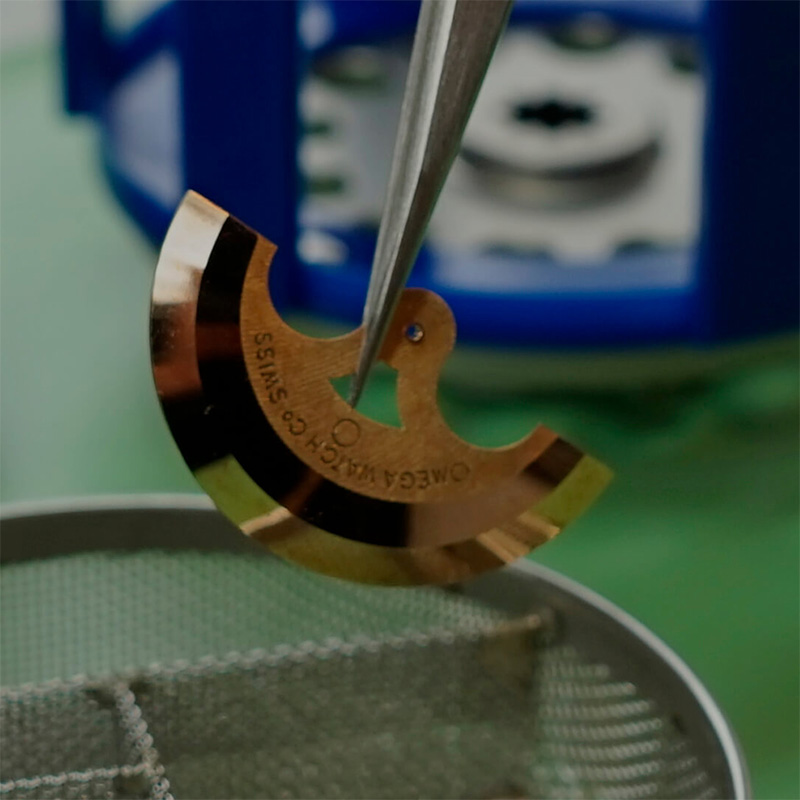

A full watch restoration goes beyond a standard service and is typically reserved for vintage models. The movement is completely stripped down and cleaned, just like in a regular service, but additional precision work is carried out to restore functionality and longevity.

This includes replacing train wheel jewels and bushes, closing holes, polishing pivots, replacing balance staffs, and re-shaping hairsprings. Each component is carefully inspected and restored to ensure smooth operation.

Completed restorations may also involve dial and hand restoration if needed. Case work and re-finishing are done simultaneously, with original crowns and glasses sourced to maintain authenticity.

Our restoration process

An introduction to the meticulous 10-step procedure for restorations.

Brands we specialise in

Ready to restore your timepiece?

Ready to restore your timepiece?

Trust our expert watchmakers for precision servicing and repairs.

Contact us today to give your watch the care it deserves.